Introduction

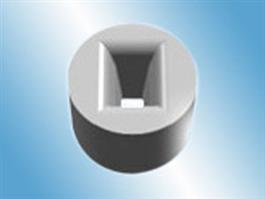

Tungsten carbide insert for rotary drill bit is used for drilling rock formations. It is often fixed on the steel drill body to give the drill strength and hardness to drill through rock formations. For different rock formations there are different cemented carbide inserts. There are also many grades that are suitable for drilling various rocks. Our tungsten carbide inserts are widely used in geology drilling. They are made from high quality tungsten carbide and are marked by high hardness, wears resistance and corrosion resistance. We mainly provide T1 and T3 cemented carbide inserts and also provide custom services for different purposes.

Applications

T1 tungsten carbide insert for making cemented carbide core drilling bits is usually used for drilling soft rock formations, while T3 is for making alloy drill bits for drilling hard rock formations. Different grades are suitable for different applications. Here we present the recommended grades and their characteristics. Clients can choose suitable grades of cemented carbide inserts for their tungsten carbide bits according to their purposes.

|

Grade

|

Hardness

|

Characteristics

|

|

YG3X (K01)

|

≥ 91.5

|

It has the best wear resistance but low impact toughness. This tungsten carbide insert is suitable for high speed finishing of cast iron, non-ferrous metal and alloys, quenched steel and alloy steel.

|

|

YG3 (K05)

|

≥ 90.5

|

Its wear resistance is second to YG3X. It is sensitive to impact and shock. This cemented carbide insert is suited for finishing and semi-finishing of cast iron, non-ferrous metal and alloys.

|

|

YG6A (K10)

|

≥ 91.5

|

This tungsten carbide insert is suitable for semi-finishing of chilled cast iron, non-ferrous metal and it alloys, and also for finishing and semi-finishing of quenched steel and alloy steel.

|

|

YG6 (K15K20)

|

≥ 90

|

Its wear resistance is lower than YG3 and shock and impact resistance is better than YG3X. This cemented carbide insert is suited for finishing and semi-finishing of cast iron, nonferrous metal and it alloys.

|

|

YG8 (K30)

|

≥ 89.5

|

With high use intensity, its shock and impact resistance is better than YG6, but wear resistance and cutting speed is lower. This tungsten carbide insert is suitable for low speed rough machining of nonferrous metal and alloys and non-metal material.

|

Advantages

1. Our cemented carbide insert are well appreciated for the features such as high mechanical strength, corrosion resistance, sturdiness, high tensile strength, compact design and corrosion resistance.

2. Tongyi tungsten carbide insert can be used to drill complex materials and can resist high drilling speed.

3. The multi-layered geometry design makes cutting much easier.

4. Samples and quotations of cemented carbide inserts will be offered upon receipt of your further requirement.

5. High-performance carbide tips are specially chosen to fit carbide bits. Fractures are avoided effectively and wear resistance is improved.

6. Our tungsten carbide inserts are manufactured complying with ISO standards.

Technical Parameters

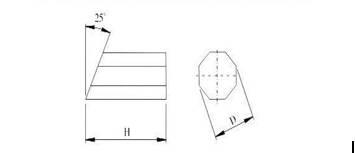

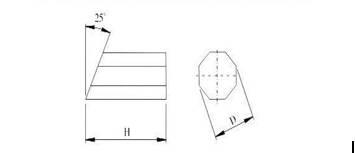

T1 Cemented Carbide Insert

|

MODEL

|

SIZE (mm)

|

|

D

|

H

|

|

T105

|

5

|

10

|

|

T107

|

7

|

15

|

|

T110

|

10

|

15

|

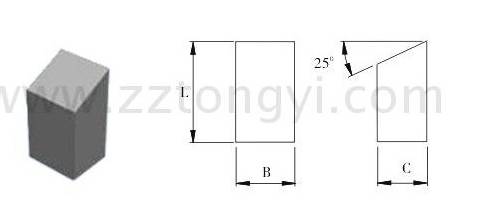

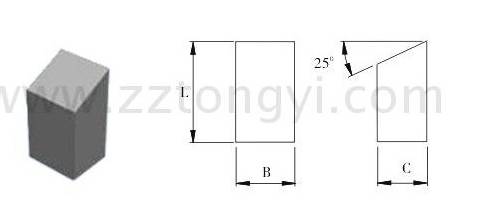

T3 Tungsten Carbide Insert

|

Model

|

Size (mm)

|

|

L

|

B

|

C

|

|

T308

|

8

|

5

|

5

|

|

T310

|

10

|

5

|

5

|

|

T310*2

|

10

|

10

|

5

|

|

T313

|

20

|

5

|

5

|

|

T313*2

|

20

|

10

|

5

|

Tips on Choosing Suitable

Cemented Carbide Insert

There are a few indicators that need to be considered when choosing suitable tungsten carbide inserts.

1. Working Stability

It is worthy considering the working stability. High machining precision will be achieved with good working stability.

2. Machining Precision

When choosing cemented carbide inserts, clients need to take the precision of drilling process into account at first. Generally the smaller the drill hole, the lower the tolerance.

3. Cost of Each Drilling Hole

The cost of each drill hole is the most important indicator when choosing tungsten carbide inserts. Drill bit manufacturers are engaged in integrating several processes into one to reduce the cost of each drilling.

4. Chip Removal and Liquid Coolant

Chip removal and liquid coolant is a very important problem in the drilling process. The deeper the drill bits go, the more difficult the chip removal is and the more liquid coolant is needed.

Established in 2002, Lanteky Carbide has rapidly grown into one of the most prominent manufacturers of cemented carbide inserts in China. In addition to tungsten carbide inserts, we also provide carbide drill bits, carbide anvils, carbide rods, carbide blanks, carbide drawing dies, carbide nozzles, carbide cutting blade, carbide brazed tips, tungsten carbide bits, carbide disc cutters and tungsten carbide rollers. Over the years, our company has established business relationships with many countries, such as Indonesia, Poland, Ukraine, Russia, Vietnam, Canada and Brazil. We have our own factories and have the ability to design and produce products according to our clients’ requirements.